Microinstrumentation Laboratory

The modular approach:

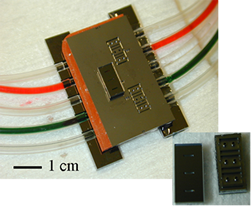

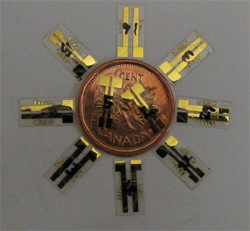

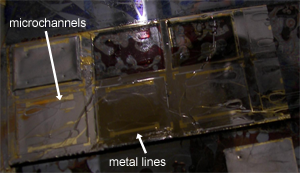

Microfluidic docking board with interconnects. Inset: Sample component (B.L. Gray et al., 2004)

Microfluidic docking board with interconnects. Inset: Sample component (B.L. Gray et al., 2004)

|

Our lab is working on using microcomponents with reusable, modular interconnects for joining microfluidic systems.

Components can be fabricated separately and later joined to form microinstruments using interconnects as chip-to-chip connections.

In addition, the interconnects can be used as world-to-chip connections with test equipment.

Using these principles, we are able to develop prototypes efficiently by optimizing components separately and joining them for microinstrumentation.

Some example projects are listed below. |

Projects |

|

|

Mechanical and Fluidic Interconnect for Joining Microfluidic Systems

|

|

|

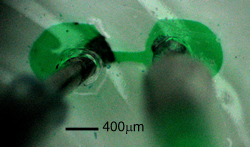

Creating microfluidic systems using a toolbox of microcomponents would enable rapid prototyping of complex microinstruments.

Our approach employs mechanical interlocking cylinder and hole structures as mechanical and microfluidic interconnect between systems,

and also for world-to-chip interconnect off-chip.

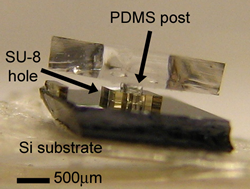

These interconnects have been made in silicon and SU-8 (B.L. Gray et al., 2004). The interconnects have also been fabricated in PDMS (S. Jaffer and B.L. Gray, 2007). Polymers have enabled fluid-tight sealing without additional gaskets, along with the opportunity to create relatively inexpensive, disposable microfluidic systems. Polymer cylindrical posts have been mechanically tested with polymer and silicon holes for disassembly forces. These interconnects are the first building block for joining microfluidic systems. |

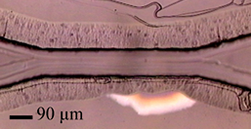

Silicon (left) and Polymer (right) snap-together interconnects for fluidic systems (B.L. Gray and S. Jaffer, 2005)

PDMS post assembled with SU-8 hole (S. Jaffer and B.L. Gray, 2007) |

|

Microneedle Array with Integrated Interconnect for Transdermal Drug Delivery

|

|

|

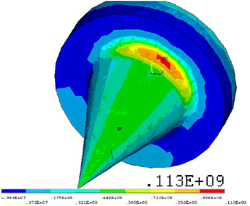

Microneedles have the capability for providing pain-free drug delivery and biofluid monitoring for hand-held and wearable

diagnostic and closed-loop drug delivery systems. Microneedles with interconnects of various inner radii were analyzed

and simulated in ANSYS to determine their flow characteristics and pressure requirements for delivery of analgesics and

antibiotics at temperatures ranging from 20 to 40 degrees.

Mechanical strength of silicon microneedles 250 microns in height were analyzed and simulated using ANSYS numerical analysis simulation package. Preliminary silicon microneedles were fabricated with integrated interconnect as demonstration components for interconnect structures. |

Simulated Tensile Stress

Simulated Tensile Stress(O.A. Lui and B.L. Gray, 2006) |

|

Non-invasive Glucose Sensor

Recently, non-invasive methods of blood glucose measurement have gained popularity. Towards building a system for this purpose, the glucose sensor has been fabricated using straight-forward fabrication techniques using inexpensive polymer, for integration with polymer microfluidic devices for blood glucose measurement.

|

Glucose sensors on flexible polymer substrates

Glucose sensors on flexible polymer substrates(J. Pater, et al., 2007) |

|

Cell Research Platforms for Endothelial Cell Analysis

|

|

|

Cell research platforms enable cellular study by providing instrumentation on the same size scale as cells which is not possible using other methods.

For example, endothelial cells (EC) line the inner walls of blood vessels, and these cells play a role in atherosclerosis, which is the leading cause of

coronary thrombosis and heart attack. Shape plays a central role in the formation of these lesions. The platform allows shape versus function studies to

be performed on ECs for which shape control is enabled by microchannel confinement

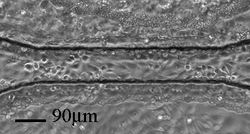

Previous work has been done for analysing endothelial cell elongation using cell research platforms with microfluidic channels made in silicon (B.L. Gray et al., 2002). Currently, SU-8 has been employed (S.M. Westwood et al., 2007) as an alternative to silicon for its inexpensive fabrication techniques and the movement towards cheaper polymer systems for microinstrumentation. SU-8 has shown to be a viable alternative to silicon in this study. |

Cell research platform in SU-8, demonstrating elongated ECs

Cell research platform in SU-8, demonstrating elongated ECs(S.M. Westwood et al., 2007). |

|

Microfluidic Channels with Integrated Interconnect

As mentioned, the integration of microfluidic interconnect with microfluidic components allows us to realize a toolbox of microfluidic components for creating various microfluidic devices. The mechanical interlocking cylindrical posts and holes have now been integrated with enclosed microchannels, designed as cell platforms for EC shape analysis. Devices fabricated in SU-8 and PDMS have been developed and pressurization tested, where the interconnects were employed as world-to-chip couplers with testing equipment (S. Jaffer, S.M. Westwood, B.L. Gray, 2007). |

|

SU-8 microchannel with interconnects (S. Jaffer, S.M. Westwood et al., 2007) |

PDMS microchannel with fluid flow (S. Jaffer, S.M. Westwood et al., 2007) |

|

Electrical Press-contacts on SU-8 for Integration of Electrical Interconnect for Microfluidic Systems

|

|

|

In previous work, we have shown mechanical assembly and fluidic pressurization of polymer interconnects.

Joining microfluidic systems with electrical capabilities will require electronic routing to the microfluidic chips.

We have fabricated metal lines on SU-8 for this purpose, showing that released substrates have higher electrical resistances than un-released substrates, due to surface stresses. Also, we have shown chip-to-chip electrical continuity. |

Metal lines on SU-8 substrates (T. Ueda et al., 2007) |

Copyright © 2007 MiL All Rights Reserved